- Apprenticeships

- Training Courses

- Lean Six Sigma

- Lean

- Introduction to Lean

- Lean Practitioner Training

- Lean Kaizen Facilitator Training Course

- Lean Mistake Proofing Training

- Lean 5S Training Course

- Lean 8 Wastes Training Course

- Lean Library (47)

- Lean Bundle (10)

- Failure Mode and Effects Analysis (FMEA) Training

- Problem Solving Training Course

- All Lean Courses

- Business Improvement

- Personal Development

- Facilitation Body Language Training

- Building Self-Esteem & Assertiveness Training

- Influencing Skills Training

- Negotiation Skills Training Course

- Building Your Personal Brand

- Active Listening Skills Training

- Stress Management Training

- Online Pressure Management Training

- All Personal Development Courses

- Management Development

- All Courses

- Consultancy / Coaching

- Resources

- E-Learning

- About Us

- Contact

- Lifetime tutor support

- Certification guaranteed

- Multiple choice exam with free retakes

£50.00 + Vat Buy Now

Home / All Courses / Lean 8 Wastes Training Course

Lean 8 Wastes Training Online Course

The 7 / 8 Wastes is one of the cornerstones of Lean thinking due to its unambiguous focus on wasteful practices. Waste is costly for businesses, both in terms of time and resources, so the identification and removal of waste can have a hugely beneficial impact on profitability.

During this training course you will learn how we define waste, how to identify it in your place of work, and then how to remove it so that it doesn’t return. Traditionally there are 7 Wastes, as part of a Lean approach, but this has recently been increased to 8 Wastes to include employee talent.

You’ll see real-life examples of the 8 Wastes of Lean in business environments and will undertake exercises that will empower you to clearly see them in your own place of work.

Because the 8 Wastes are so general they can be, and regularly are, applied in any job, function or industry – many people even apply them at home!

This course is available online, in the classroom at one of our training venues or we can come to you. You can be sure that however you choose to learn, you’ll get the same great quality and cover the same content.

By learning the 7/8 Wastes, you’ll be able to increase productivity, increase output without increasing costs and improve staff satisfaction. By removing waste, customer satisfaction also improves as there are fewer defects, mistakes and delays.

During the course you will learn:

- The concept of Lean and how the 7 / 8 Wastes are associated with it

- The 7 or 8 Wastes of Lean – known by the acronym DOWNTIME or TIMWOOD

- How to energise staff to understand the benefits of removal of the 7 / 8 Wastes

- How to identify and eliminate waste

- What a waste walk is, and how to do one

- The benefits of removing waste and the potential savings

- How to identify the 7 / 8 Wastes in your own business

The duration and cost of the course will depend on how you choose to learn. Look at the options below to learn more.

Like many things in life, the 7 / 8 Wastes is a simple concept but applying it can completely transform a business. Understanding how you are being wasteful and redirecting those resources into more productive channels is vitally important – particularly in today’s turbulent economic climate.

After your training you will:

- Understand the principles of Lean

- Understand the 7/8 Wastes, how to identify them and eliminate them

- Know the mnemonics TIMWOOD and DOWNTIME

- Understand the saving potential of waste elimination

- Appreciate waste and why it is vital to eliminate it

Lean 7 / 8 Wastes is a vital business methodology that leads to reduced costs and improved quality. Familiarity with the methodologies and processes is important for a range of roles, not just those with operational applications.

Online Lean 8 Waste Training Course

We understand that not everyone can attend a face-to-face classroom course, due to time, geographic or financial reasons, but you don’t need to either. The newly designed Virtual Yellow Belt course, combines the perfect blend of the flexibility of an online course and the experience of classroom learning, through live expert led sessions, virtual collaboration and breakout rooms.

This Virtual Classroom course allows you to learn anywhere, as long as you have an internet connection and a device to view it on. Our dedicated Master Black Belts teach the same materials covered in our face-to-face courses, so you’ll get the same great experience and learning you’d expect from us.

Select modes of training

Lean 8 Wastes Training Course

Online

£50 Ex. Vat

£60 Inc. Vat

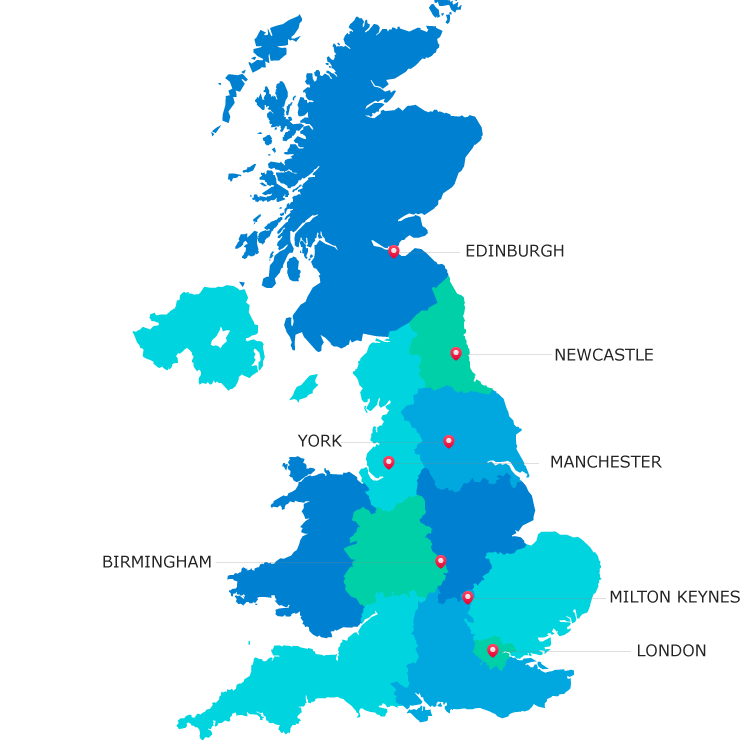

Our Most Popular Locations

Our Six Sigma, Lean and Kaizen classroom training is available in major locations, towns and cities across the UK. Here’s where we get the most demand.