- Apprenticeships

- Training Courses

- Lean Six Sigma

- Lean

- Introduction to Lean

- Lean Practitioner Training

- Lean Kaizen Facilitator Training Course

- Lean Mistake Proofing Training

- Lean 5S Training Course

- Lean 8 Wastes Training Course

- Lean Library (47)

- Lean Bundle (10)

- Failure Mode and Effects Analysis (FMEA) Training

- Problem Solving Training Course

- All Lean Courses

- Business Improvement

- Personal Development

- Facilitation Body Language Training

- Building Self-Esteem & Assertiveness Training

- Influencing Skills Training

- Negotiation Skills Training Course

- Building Your Personal Brand

- Active Listening Skills Training

- Stress Management Training

- Online Pressure Management Training

- All Personal Development Courses

- Management Development

- All Courses

- Consultancy / Coaching

- Resources

- E-Learning

- About Us

- Contact

Effective, engaging, practical Lean Yellow Belt course

- Online, eLearning, In house or virtual training you choose

- 1 months access no matter your training method worth £199 included

- Exam included (unlimited retakes)

- Certificate included

- Lifetime support via phone and email

- Interactive, engaging sessions by Lean experts

- Learn every aspect of Lean effectively

£199.00 – £300.00 + Vat Buy Now This product has multiple variants. The options may be chosen on the product page

Lean Yellow Belt Training – Grasp the Principles and Key Problem-Solving Skills.

Our introductory Lean course covers Lean methodologies, equipping you with essential tools and techniques to become a proficient Lean Yellow Belt. Learn how to apply Lean practices to enhance your business and everyday life.

What sets our training apart is the lifetime support you’ll receive. Our dedicated team at 100% Effective is committed to your success, providing ongoing guidance and assistance throughout your Lean journey.

Upon successful completion of the course, you’ll earn a globally recognised full certification, validating your expertise in Lean methodologies and unlocking exciting career opportunities.

Exams are included to assess your progress and reinforce your understanding of the material. Our training encompasses all Lean essential tools and techniques, providing a comprehensive foundation for your role.

Rest assured, our training is developed by industry experts with extensive experience in Lean methodologies. Learn from the best and gain practical knowledge to apply immediately.

Our online e-learning training offers flexibility and convenience, allowing you to learn at your own pace and revisit the material as needed. Choose virtual or in-house training options to suit your preferences and availability. Online elearning is included FREE for Virtual and in-house training.

Seize this opportunity to propel your career with our Lean Yellow Belt training course. Join industry leaders who have harnessed Lean methodologies for unparalleled success. Enroll now and embrace a future of continuous improvement and professional excellence.

About our Lean Yellow Belt course

Course Overview: Lean Yellow Belt – Embrace Essential Lean Elements

The Lean Yellow Belt course is an indispensable qualification for individuals seeking to understand the fundamental principles of Lean methodology. This course not only outlines the key elements of Lean and problem-solving but also empowers participants to make quick and simple improvements. By completing this program, you will gain the necessary skills to support others in more complex business improvement activities and embark on your journey of Lean knowledge. The highly practical curriculum starts with the core principles and tools of Lean methodology, enabling participants to achieve substantial improvements and optimal outcomes.

Key Course Topics:

- Introduction to Lean and its Key Principles:

- Grasping the core concepts and philosophy of Lean methodology.

- Exploring the wide-ranging benefits of Lean implementation across various industries.

- Cultivating a culture of continuous improvement to achieve lasting success.

- Mastering Essential Lean Tools for Optimal Results:

- Acquiring and applying vital Lean tools to identify and eliminate waste.

- Leveraging Lean principles to optimise processes, minimise lead time, and enhance quality.

- Strengthening problem-solving skills through hands-on experience with Lean methodologies.

- Understanding the Five Principles of Lean

- Identifying and Eliminating the Seven (or Eight) Wastes.

- Solving Problems using essential tools.

This course offers a practical learning experience, combining theoretical knowledge, hands-on practice, and interactive exercises. Participants will emerge with newfound confidence and skills, fully prepared to effectively implement essential Lean principles within their organisations. Join us on this transformative journey towards a future of Lean excellence and unparalleled efficiency.

What will I learn with the virtual or online Lean Yellow Belt training?

The Lean Yellow Belt course aims to equip you with foundational knowledge and skills in Lean methodologies, offering a comprehensive understanding of Lean principles and basic problem-solving tools and techniques. Throughout the course, you will delve into theory, practice essential tools, participate in simulations, and gain valuable insights into Lean practices. Whether you choose online learning, classroom sessions, or on-site training, we provide flexible options to suit your preferences. Join us on this transformative journey to unleash the potential of Lean and elevate your career as a Lean Yellow Belt!

Introduction to Lean

1.1 Tennis Ball Game

1.2 Lean Overview

1.3 Examples of 8 Wastes

1.4 Lean Fundamentals, Culture and Roles

1.5 Project Benefits

Understanding the Customer

2.1 Voice of the Customer

Map the Value Stream

3.1 Process Mapping Introduction

3.2 Swimlane Diagrams

3.3 Spaghetti Diagrams

Establish Flow

4.1 Establishing Flow

Tools to Eliminate Waste and Implement Pull

5.1 Detailed Design – 5S

5.2 Detailed Design – Visual Management

5.3 Detailed Design – Mistake Proofing

Strive for Perfection

6.1 Gemba Walk

Problem Solving

7.1 DMAIC Roadmap

7.2 DMAIC v PDCA

7.3 Team Selection and Launch

7.4 Define Phase Overview

7.5 Project Charter

7.6 Problem Statements

7.7 In & Out of Scope

7.8 SMART Goals

7.9 SIPOC

7.10 Project Planning

7.11 Project Benefits

7.12 Define Phase Summary

7.13 Gate Reviews

7.14 Measure Phase Overview

7.15 Visualising Data Introduction

7.16 Time Series Plots

7.17 Frequency Plots

7.18 Scatter Plots

7.19 Check Sheets

7.20 Implementing Quick Wins

7.21 Measure Summary

7.22 Analyse Overview

7.23 Introduction to Identifying Potential Root Causes

7.24 Brainstorming

7.25 Brainwriting

7.26 Affinity Diagrams

7.27 5 Whys

7.28 Cause and Effect Diagrams

7.29 Analyse Summary

7.30 Improve Phase Overview

7.31 Generate Solutions Part 1

7.32 Generate Solutions Part 2

7.33 Introduction Priortise Solution Ideas

7.34 Prioritising Solutions Ideas

7.35 Validate the Solution

7.36 Validate Benefits

7.37 Improve Summary

7.38 Control Phase Overview

7.39 Confirming Improvement

7.40 Closing Out

7.41 Control Summary

Learning outcomes from Lean Yellow Belt Certification

Lean methodologies present significant cost savings and quality improvements for industries worldwide. Thus, having a Lean Yellow Belt or receiving training within your organisation brings immense advantages. When all staff understand lean fundamentals and problem-solving, they can actively support business development.

As a Lean Yellow Belt, you’ll support others in implementing complex Lean principles and identify solutions to problems within any business area yourself.

Upon completing the Lean Yellow Belt training, you will:

- Grasp the key principles of lean, particularly in identifying and eliminating waste and non-value-added activities from processes.

- Master essential Lean and problem-solving tools, applying them effectively in your workplace.

- Gain confidence in problem identification and highlighting.

- Achieve tangible improvements in efficiency and quality.

- Strengthen personal skills.

- Boost customer satisfaction and stakeholder confidence.

- Earn professional recognition for your Lean expertise.

Unlock the potential of Lean methodologies, drive growth in your career and organisation. Invest in Lean Yellow Belt training today to achieve efficiency, cost savings, and a culture of continuous improvement.

Expert Trainers Empowering Your Lean Journey

- With extensive expertise in business improvement, our trainers have successfully supported clients across five continents, driving process improvements as Lean experts. Over the years, we have trained thousands of delegates as Lean Yellow Belts.

Added Value:

- No matter your preferred learning method, we offer access to our eLearning course (worth £199) for a whole month, allowing you to retake the course as many times as needed. This valuable resource proves especially beneficial when you begin running your first sessions.

Lifetime Support:

- Rest assured, all our courses include unlimited support via phone or email. Whenever you encounter challenges or need assistance, our Master Black Belts are here to help you.

Highly Practical Training:

- Our training options are designed to provide hands-on, practical experience delivered by experts who have been in the trenches, witnessed challenges, and achieved success. Enriched with real-life stories, examples, and experiences, the training equips you to tackle any questions that arise.

Full Worldwide Recognised Certification Included:

- We take care of everything, ensuring you obtain full certification without the need for further recertification. Additionally, the verification of your qualification is included in the course price.

Unrivaled Lean Yellow Belt Toolkit:

- As the sole course offering all Lean Yellow Belt tools and techniques, you will gain comprehensive insights and skills to make a significant impact on your improvement journey.

Who Should Attend our Lean Yellow Belt Training Course?

The Lean Yellow Belt course caters to professionals across diverse industries who are eager to grasp Lean methodologies. The following roles stand to benefit significantly:

- Managers and Supervisors: Enhance their capabilities in process management, fostering efficiency and continuous improvement.

- Quality Managers and Engineers: Strengthen problem-solving skills, reduce waste, and drive process improvement initiatives.

- Project Managers: Gain a comprehensive understanding of Lean principles to enhance project efficiency.

- Continuous Improvement Professionals: Embark on their Lean journey, equipping themselves with essential Lean knowledge and tools.

- Senior Executives and Leaders: Cultivate a culture of Lean thinking within their organisations and drive wide-scale Lean improvements by mastering the fundamentals of Lean.

If you want to:

- Grasp essential Lean tools and techniques,

- Acquire problem-solving skills,

- Support fellow Lean professionals,

- Initiate your Lean Journey for enhanced career prospects, and

- Elevate your business performance,

Then the Lean Yellow Belt course is tailor-made for you!

100% Effective certification is included in the price and requires completion of our online exam. Our process:

- End of course exam – understand the theory

- Multiple choice questions

- Unlimited retakes

- Open book covering full curriculum

- Pass mark = 70% (our pass rate is 90% first time)

- Validate your certification – all certificates come with a unique number so employers can validate your certificate

- Certification for life! There’s no need to pay to re-certify after a number of years

- Option to deliver a project which will be reviewed by Master Black Belts included in the price.

Our curriculum covers all aspects of Lean. This certification proves your knowledge of Lean to any business or individual.

FAQ's

What is the difference between Lean Yellow Belt and Lean Green Belt:

- A Lean Six Sigma Yellow Belt covers all the essential skills associated with Lean and problem-solving.

- Lean Six Sigma Green Belts take these skills to a more advanced level with additional tools and techniques, enabling them to solve more complex problems.

What is a Lean Green Belt’s Worth to a Company:

- Lean Green Belts are of higher value to their companies as they possess the capability to solve more complex problems compared to Lean Yellow Belts.

Difference between Lean Green Belt and Lean Black Belt:

- Lean Green Belts typically focus on solving problems within their own function or department.

- Lean Black Belts have the capability to work company-wide on more strategic and complex problems.

Black Belt’s Roles and Responsibilities:

- Black Belts spend more time working on change management aspects and engage in more detailed data analysis.

- They are held to a higher standard as they work on larger and more significant improvement projects.

- Black Belts must learn and master more tools and techniques to handle their challenging roles.

Prerequisites for Lean Yellow Belt Training:

- There are no prerequisites for attending the Lean Yellow Belt training course, making it accessible to professionals from various backgrounds and roles.

Training Delivery Options: The Lean Yellow Belt course is available in two formats:

- 1-day Virtual Classroom Lean Yellow Belt

- Online eLearning courses

Virtual Classroom Experience:

- Virtual classes are conducted using Zoom, providing interactive and engaging courses for an excellent learning experience. The virtual classroom can be accessed globally, with limited class sizes to ensure active participation and engagement. Master Black Belts deliver the training, sharing their experience, stories, and examples to provide practical insights into Lean implementation.

Lean Training Course Instructors:

- The Lean Yellow Belt courses are delivered by friendly and highly experienced trainers who hold the title of Master Black Belt. They have trained and coached delegates from around the world and have extensive experience in delivering improvement projects and supporting others.

In-House Delivery Option:

- For organisations seeking a more tailored approach, the Lean Yellow Belt course can be delivered in-house. It can be conducted in-person at the organization’s office or a chosen location, or as a live virtual training course, with the content adapted to suit the specific needs of the company.

In-House Lean Yellow Belt Course, please enquire below:

Don’t delay, start your learning today:

Select modes of training

Lean Yellow Belt Training

online

£199 Ex. Vat

£238.8 Inc. Vat

Lean Yellow Belt Training

virtual

22nd January 2024

£300 Ex. Vat

£360 Inc. Vat

Duration: 1 Day

Lean Yellow Belt Training

virtual

29th January

£300 Ex. Vat

£360 Inc. Vat

Duration: 1 Day

Lean Yellow Belt Training

virtual

12th February

£300 Ex. Vat

£360 Inc. Vat

Duration: 1 Day

Lean Yellow Belt Training

virtual

15th April

£300 Ex. Vat

£360 Inc. Vat

Duration: 1 Day

Lean Yellow Belt Training

virtual

13th May

£300 Ex. Vat

£360 Inc. Vat

Duration: 1 Day

Blogs & Articles

News, insights and infographics

- By Admin User

Process Mapping: A Vital Skill for All Managers In a highly competitive business environment, organisations strive to optimise their operations to enhance productivity, minimise costs, and deliver superior value to their customers. Amid these objectives, process mapping has emerged as...

More Info

- By Admin User

In a competitive business landscape, organisations strive to maximise efficiency and enhance productivity. To achieve these objectives, companies must have a clear understanding of their processes, identify bottlenecks, and streamline operations. This is where process mapping emerges as a powerful...

More Info

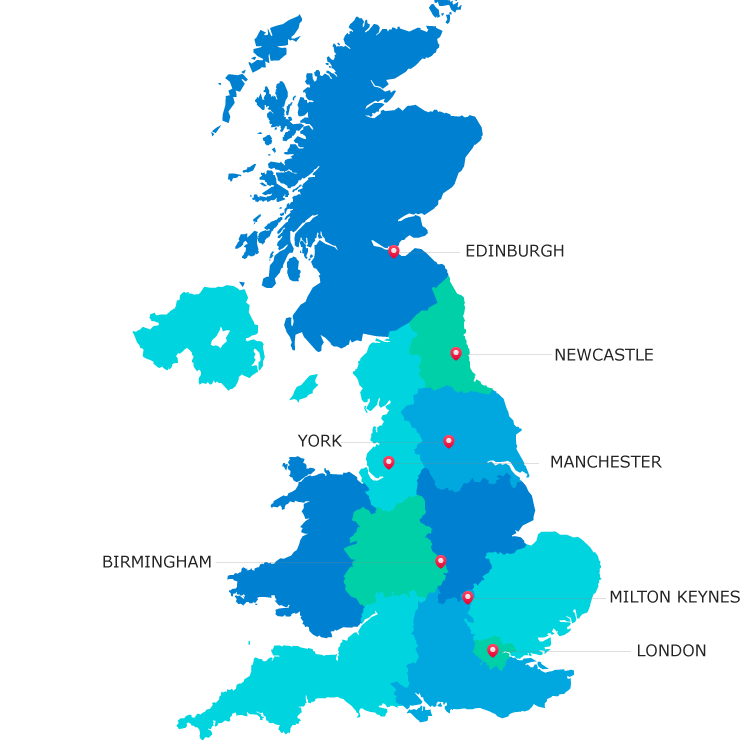

Our Most Popular Locations

Our Six Sigma, Lean and Kaizen classroom training is available in major locations, towns and cities across the UK. Here’s where we get the most demand.