- Apprenticeships

- Training Courses

- Lean Six Sigma

- Lean

- Introduction to Lean

- Lean Practitioner Training

- Lean Kaizen Facilitator Training Course

- Lean Mistake Proofing Training

- Lean 5S Training Course

- Lean 8 Wastes Training Course

- Lean Library (47)

- Lean Bundle (10)

- Failure Mode and Effects Analysis (FMEA) Training

- Problem Solving Training Course

- All Lean Courses

- Business Improvement

- Personal Development

- Facilitation Body Language Training

- Building Self-Esteem & Assertiveness Training

- Influencing Skills Training

- Negotiation Skills Training Course

- Building Your Personal Brand

- Active Listening Skills Training

- Stress Management Training

- Online Pressure Management Training

- All Personal Development Courses

- Management Development

- All Courses

- Consultancy / Coaching

- Resources

- E-Learning

- About Us

- Contact

FMEA Training – Effective, engaging, practical certification course in Failure Mode and Effects Analysis Online or Classroom

- 2 month online FMEA training access included in all training methods worth £150

- Lifetime support via phone and email

- Online, eLearning, In house or virtual training you choose

- Certificate included

- Exam included (unlimited retakes)

- Interactive, engaging sessions by FMEA experts

- Learn the key Risk Management Tool – FMEA

£150.00 – £250.00 + Vat Buy Now This product has multiple variants. The options may be chosen on the product page

Enrol and certify in our FMEA Training course for a comprehensive introduction to the step-by-step method of conducting Failure Mode and Effects Analysis (FMEA). This course defines the crucial role, methodologies, and implementation of FMEAs as a fundamental element of preventive action programs. Participants will actively engage in determining FMEA objectives, analysing potential failure causes and effects, assessing risks, and developing effective preventive action plans.

Our interactive FMEA Training includes valuable resources such as handouts, practice exercises, editable templates, real-world examples from design, process, and service contexts, quizzes, and full certification.

Learn process and design FMEA approaches in our comprehensive training program available in online, virtual or in house formats. A complimentary 2-month access to the online FMEA training course and FMEA certification is included.

About this course

Prevention is always preferable to dealing with the consequences later on! Originally developed in the 1960s for the aerospace industry, Failure Mode and Effects Analysis (FMEA) is a systematic approach for identifying and investigating potential weaknesses in design or processes.

Join our online FMEA training or Virtual or In house FMEA training course to become a master of Failure Mode Effects Analysis. This technical risk analysis tool helps assess and prioritize risks associated with product or process failures, enabling effective mitigation strategies.

By the course’s completion, you will possess the skills to conduct a thorough Failure Mode Effects Analysis. Whether you’re a member or leader of an analysis team utilising methodologies like Lean Six Sigma, this analysis technique will greatly aid your problem-solving efforts.

You do not need any experience of FMEA to undertake this FMEA certification course.

What will I learn?

Our FMEA training courses will explain not only what FMEA is but walk you through the completion of Process and Design FMEA’s.

FMEA is most noticeably used in industries where there is a serious risk associated with failure, such as aviation, the Armed Forces, space exploration & manufacturing. However, it is also common across the rest of industry where failures may not be so dangerous but could be hugely expensive or very damaging to the company.

During this course, you will cover the following FMEA topics:

- Introduction and background to FMEA

- The business needs for FMEA in product and process design – what, why & when

- Types of FMEA – system, design, process and machinery

- FMEA Inputs

- Team membership and running an FMEA -set up and roles

- The FMEA Template

- Getting started – project management, scoping and objectives

- Introduction to FMEA 7 step analysis methodology

- Structure Analysis including use process flow diagrams

- Function Analysis including Ideal Function definition and specification

- Failure Analysis including Mode, Cause and Effects identification

- Use of Failure Chain to correctly distinguish between Failure Mode, Cause and Effects

- Severity and classification – definition, examples and questions

- Occurrence – definition and questions

- Controls and detection – definition, examples and questions

- Risk Analysis using Severity, Occurrence and Detection Rating Scales

- Action prioritisation for Design and Process FMEA

- Optimisation by developing appropriate actions

- Common mistakes with Failure Mode Effect Analysis

- Examples / case studies: product design FMEA & process FMEA

- Implementing FMEA’s in an organisation

- FMEA Certification

- Lines and symbols used in process mapping

Learning outcomes

Learning how to complete Failure Modes and Effects Analysis is hugely beneficial to your company, but it also provides you with key skills you can continue to use throughout your career.

Benefits of FMEA Certification

- Improved quality, reliability and safety

- Increased customer satisfaction

- Identifies critical to quality elements of a process, product or service

- Documents risk reduction activities

- Reduces development time and costs

- Reduces warranty claims, returns and complaints

Benefits to the individual

The ability to:

- Understand the purpose of an FMEA and its general benefits

- Recognise the difference between a product design FMEA and a process FMEA

- Recognise the importance of a team approach to FMEA completion

- Understand how to set the scope for an FMEA project

- Understand guidelines for rating severity, occurrence and detection

- State how to prioritise and manage risks

- The key steps in design / process FMEA (Failure Mode Effect Analysis) so that you can deploy in your business

- Be capable of explaining and using the Calculation of Risk Priority Number (RPN)

- Identify and eliminate potential failure modes early

- Apply mistake proofing techniques

- Work with a team to collect data

- Understand where to apply FMEA

- FMEA certification

Our trainers are experts

- As experts in business improvement we have supported clients on 5 continents to reduce risks using FMEA’s. We have trained & certified thousands of delegates in FMEA.

Added Value

- No matter your learning method you will receive access to our online FMEA training course (worth £150) for 2 months allowing your training to retake the course over and over again. This is highly valuable when you run your first sessions

Lifetime support

- All our courses come with unlimited support via phone or email. When you have a problem or need support our Master Black Belts will help you.

Highly practical training

- All our training options provide practical training from experts who have been there, seen it and done it. We will enrich the training with stories, examples and experiences to answer your questions.

Who Should Attend?

This comprehensive course is tailored to meet the needs of a wide range of professionals dedicated to enhancing customer satisfaction and mitigating product liability risks. Whether you’re involved in product development, design, business improvement, management, manufacturing, engineering, quality control, or process engineering, this course is designed to empower you with the knowledge and skills necessary to excel in your role.

Specifically, this course is suitable for:

- Product developers seeking to devise effective strategies for new product introduction and reduce “time-to-market” concerns.

- Professionals engaged in product, process, or service design, aiming to optimise their design capabilities.

- Individuals involved in business improvement, process development, or continuous improvement initiatives, including Lean Six Sigma Belts.

- Managers who recognise the importance of risk management and wish to understand how to identify and mitigate potential risks.

- Manufacturing and engineering managers striving to enhance manufacturing capabilities, predict product yield, and improve cross-functional technical communications.

- Design engineers responsible for new product design and introduction, aiming to improve customer definition and incorporate manufacturing feedback.

- Quality/reliability managers and engineers interested in fostering awareness and practical application of risk reduction tools within their organisation.

- Process engineers actively engaged in identifying and implementing solutions to minimize risk factors.

- Systems designers keen on reducing risk and enhancing overall performance.

No matter your role or industry, this course will equip you with invaluable insights and practical tools to tackle challenges, reduce risks, and drive continuous improvement within your organization. Don’t miss this opportunity to enhance your professional expertise and make a lasting impact. Enrol in our course today!

FMEA certification

100% Effective’s FMEA certification is included in the price and requires completion of our online exam. Our process:

- End of course exam – understand the theory

- Multiple choice 20 questions

- Unlimited retakes

- Open book covering full curriculum

- Pass mark = 70% (our pass rate is 90% first time)

- Validate your certification – all certificates come with a unique number so employers can validate your certificate

- Certification for life! There’s no need to pay to re-certify after a number of years

Our curriculum covers everything you need to know about FMEA’s. This FMEA certification proves your knowledge of FMEA.

FAQ’s

Where can I attend this training?

- Our 1 day Virtual Classroom FMEA and online FMEA Training courses can be attended from anywhere in the world. Virtual classes start at 09:00 until 17:00 UK time

How do Virtual Classes work?

- Using zoom we provide interactive and engaging courses that ensure you have an excellent learning experience. Our virtual classroom can be accessed globally, we limit sizes to ensure everyone can participate and engage. Our Master Black Belt provide their experience, stories and examples so you can not only learn the theory but how to effectively run process mapping sessions.

Who delivers your FMEA training courses?

- Our FMEA courses are delivered by our friendly and highly experienced trainers. As Master Black Belt they have trained and coached delegates from all over the world. They have also delivered hundreds of improvement projects and supported thousands of others to do the same.

In-House Delivery

- We can also deliver this FMEA course just for your organisation. We can do this in-person at your office or a location of your choice or as a live virtual training course. For companies wishing to take advantage of our in house option we can adapt the training to suit your exact needs.

How do I book this course?

- To enrol on our online FMEA training, virtual or classroom courses click on Buy now. This will open up your basket where you can proceed to checkout. You will have to register if you have not purchased from us before. This enables you to get instant access once you have paid.

- For in house courses please get in touch with us through our contact form.

What if I am booking the course for somebody else?

- When you purchase please send us an email or put in the description the name and email address of the person you are buying for. We will then arrange for their access

What if I want to pay via a PO or invoice?

- No problem please contact us to request an invoice via the contact form.

How do I access my course?

- Once payment is received you will be able to click the Training Portal button at the top of our web page. Click that and login in. You will be able to access your training course in our Training portal.

How do I access my certificates?

- Each certificate you earn is listed in your certificate area in the Training Portal. Simply login and you can access all your certificates.

Select modes of training

Failure Mode and Effects Analysis (FMEA) Training

online

£150 Ex. Vat

£180 Inc. Vat

Duration: 10 Hours

Failure Mode and Effects Analysis (FMEA) Training

virtual

26th November 2024

£250 Ex. Vat

£300 Inc. Vat

Duration: 1 Day

Failure Mode and Effects Analysis (FMEA) Training

virtual

10th February 2025

£250 Ex. Vat

£300 Inc. Vat

Duration: 1 Day

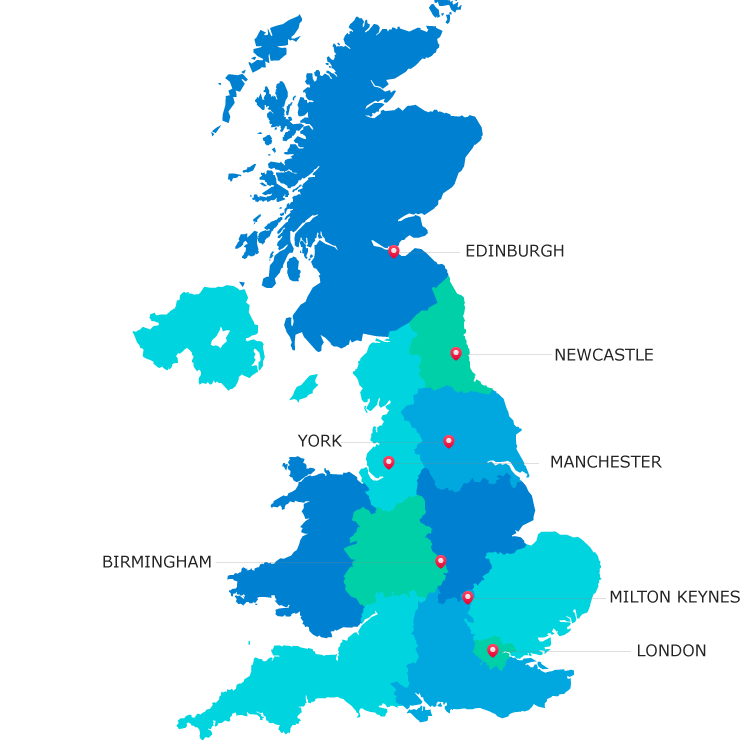

Our Most Popular Locations

Our Six Sigma, Lean and Kaizen classroom training is available in major locations, towns and cities across the UK. Here’s where we get the most demand.

Blogs & Articles

News, insights and infographics

- By Admin User

In today's competitive business landscape, ensuring the quality and reliability of products and designs is paramount. One powerful tool that helps businesses mitigate risks and enhance their offerings is Failure Mode and Effects Analysis (FMEA). FMEA is a structured method...

More Info