- Philippa McIntosh

- September 25th, 2023

Business improvement comes with a wide array of tools and techniques to help you make your processes and place of work as efficient and productive as possible.

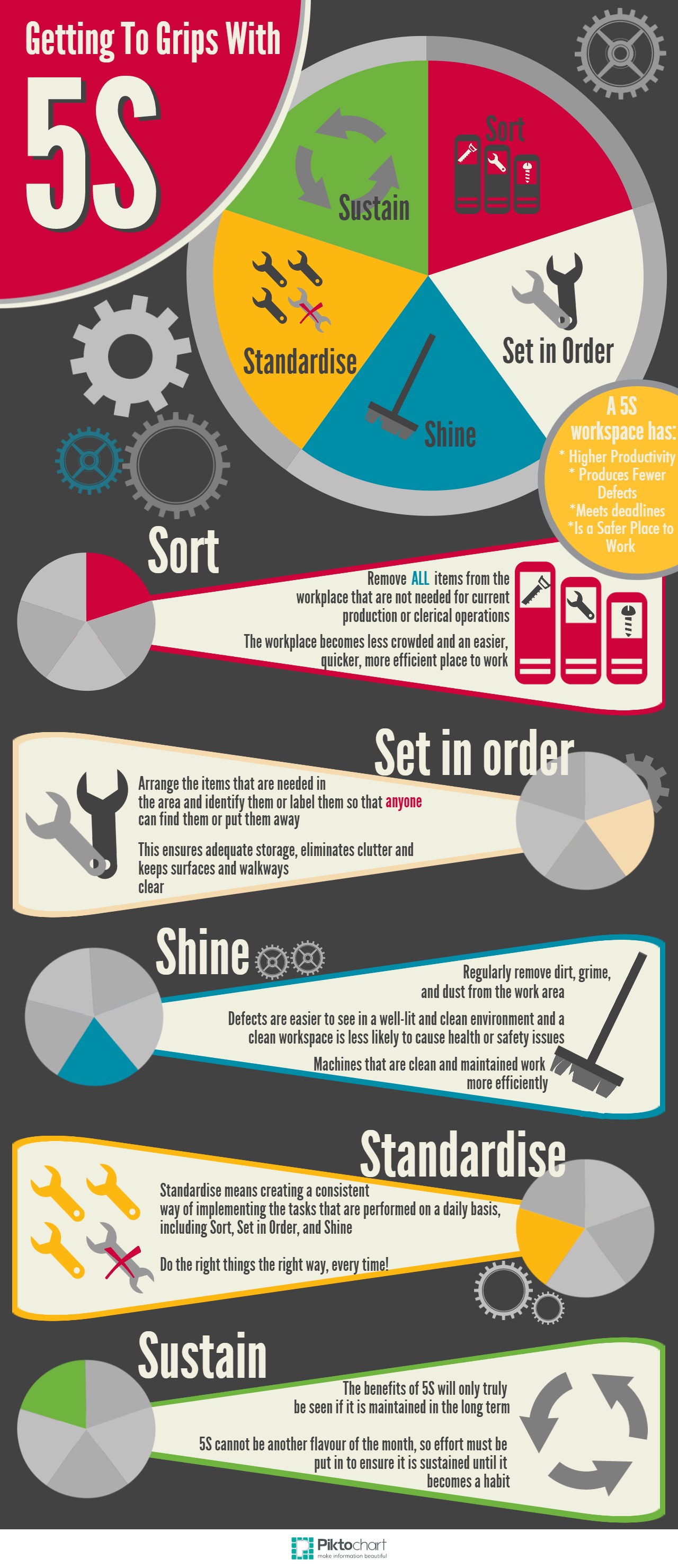

5S – which stands for Sort, Set in order, Shine, Standardise and Sustain (and occasionally Safety) – started out in warehouses as a way to ensure tools were easy to find, limit the chances of damage to products or people and improve the flow of work around the shop floor. The idea being that if there is a place for everything, and everything is in its place, significantly less time will be wasted looking for items so more of your workforce’s time is productive.

However, there is more to 5S than just having a bit of a tidy up! Take a look at our infographic to learn the basics.

If you enjoyed this infographic why not take a few moments to learn more about our 5S and Visual Management training. You can do it online, in the classroom or – if there are a few of you – we can come to you at your place of work. Find out more below.